Fighting the climate crisis with technology

Innovation plays an important role in the fight against global warming. A tour of a few especially promising research projects.

The analogy with the cheese bell occurred to geologist Frank Schilling before a lecture. He often takes part in panel discussions where he explains what he and his team are up to so deep underground. “You can think of the formation we work with as something like a cheese bell,” Schilling says. CO2 is fed into this cheese bell from below. It rises and gets trapped under the curved layer of rock above. “That’s how CO2 storage works,” he says. “The gas can’t get out from under it anymore.”

Frank Schilling is a professor of technical petrophysics at the Karlsruhe Institute of Technology (KIT) and was a leading expert on a method that is getting a growing amount of attention in the fight against the climate crisis: carbon capture and storage (CCS), a process in which carbon dioxide is extracted from the atmosphere and stored underground. It is a way for clever engineering to save the climate – or so it is hoped. In Norway this technology has already been in use for a long time, but in Germany it has not gone beyond a pilot plant “even though we were at the cutting edge of research in the EU for many years,” Schilling says.

Innovations can play an important role in fighting the climate crisis. To do their part, researchers in Germany are taking a variety of approaches, including not only CO2 storage but also more efficient ways of using geothermal heat, high-tech solar cells, the batteries of the future, or synthetic fuels. And it is clear that all of these technologies can only make a partial contribution to climate action; experts agree that the top priority has to be in reducing emissions. But the reverse is equally true: There is no way to win the fight without scientific research and the innovations it produces.

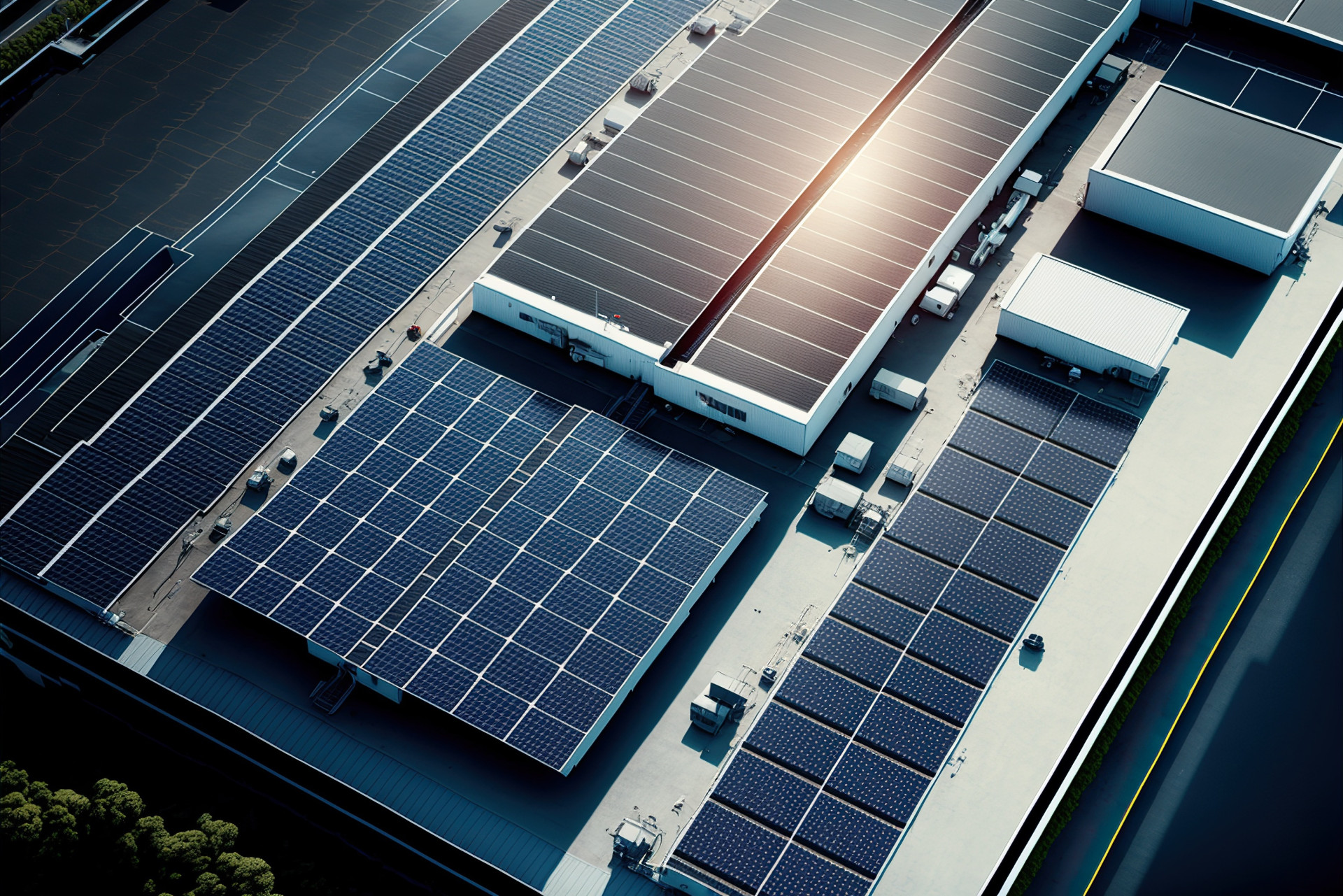

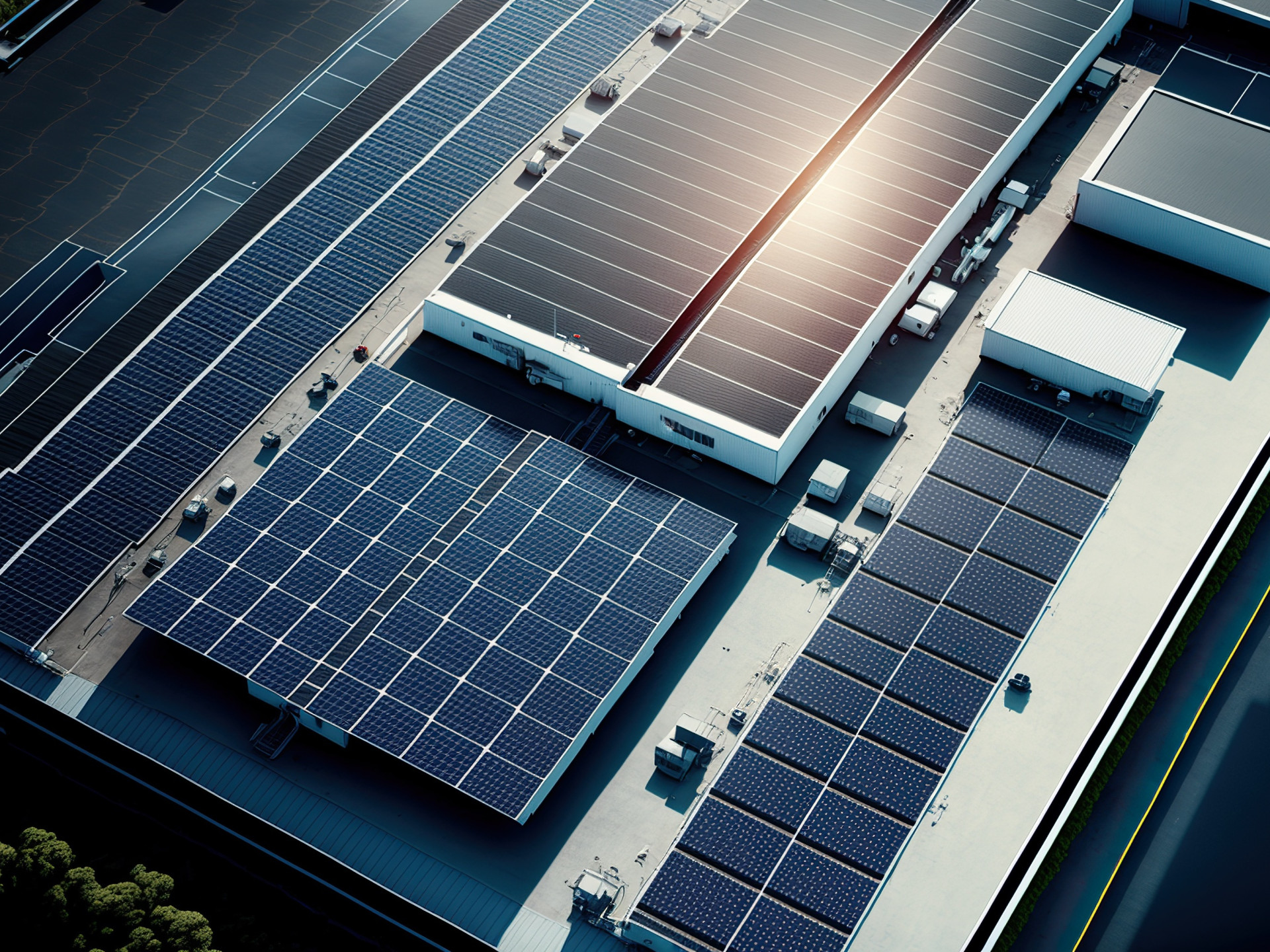

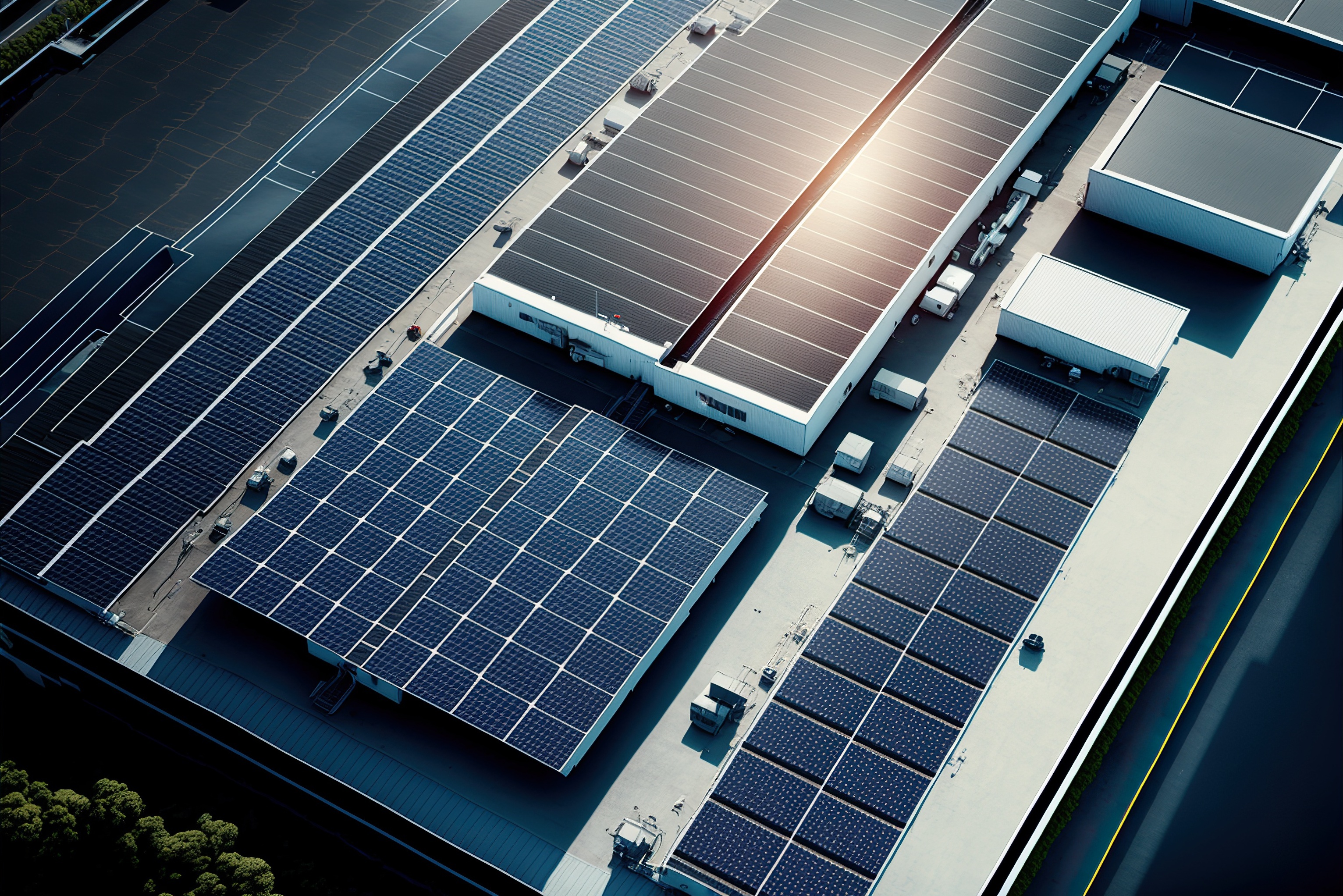

Photovoltaics in the energy transition

When speaking of the energy transition, Rutger Schlatmann, head of the Competence Centre Photovoltaics Berlin (PVcomB) at the Helmholtz-Zentrum Berlin, says "We’re in a crucial phase for photovoltaics now. And the good news is that the research sector in Europe, and particularly in Germany, is much bigger and stronger than one might expect given the remaining domestic industrial capacity.” Asia now leads in production, but many important innovations are conceived in the EU, according to Schlatmann. He has been conducting photovoltaics research for decades, and has to smile when he thinks back to its beginnings. “When I began to do research, almost nobody took this field seriously. But solar power has had the lowest production costs for several years now. It’s more economical than oil and gas, and much cheaper than nuclear power, even though it still has enormous potential for further technological improvements.” Researchers are working on ways to get even more energy from sunlight and to install photovoltaic systems not only on roofs but also to integrate them in facades.

Use of power-to-X technology

Many efforts involving hydrogen show similar promise. There is a lot of hope for hydrogen in the energy transition, but so far there has been no breakthrough that would make it efficient to produce at industrial scales. Typical applications include renewable energy. At peak times, when there is more solar or wind power available than is needed, the excess energy can be used to produce hydrogen via electrolysis. In the Helmholtz Association alone, many research teams are working to make the technology more usable, including teams at the Helmholtz-Zentrum Hereon in Geesthacht and the Helmholtz Centre for Environmental Research – UFZ in Leipzig. For example, the UFZ is part of a network called Hydrogen Saxony. “Our approach involves combining process engineering with biology,” says Andreas Schmid, who heads the photobiotechnology department. “We’re already thinking about applications as we do our research.” So the network also includes companies that are involved in development with a view to industrial-scale implementation.

KIT in Karlsruhe is taking a broader-based approach with Energy Lab 2.0, where expertise from all fields of energy research comes together at a huge site. The most promising ideas are analyzed, simulated and tested there. The site features a variety of battery storage units, a micro gas turbine combined heat and power plant, electrolysis systems, and complete model homes for testing how the different technologies work together. Visitors strolling through the site see a lot of high-tech containers jammed with everything that might be needed to build the electrical grids of the future. For example, there is a power-to-gas system in which surplus electricity from renewable energy sources is stored on-site in gaseous form and a power-to-liquid system for testing a similar process using a liquid storage medium. In addition to scientists from KIT, staff from Forschungszentrum Jülich and the German Aerospace Center (DLR) also work at Energy Lab 2.0. Far and wide, such a concentration of expertise can be found nowhere else; it has the largest renewable energy research infrastructure in all of Europe.

Further use and storage of CO2

In a laboratory just a few kilometers away, KIT researchers are working on a way to process CO2 usefully immediately after it is extracted from the atmosphere. In a multistage process, their NECOC (NEgative CarbOn dioxide to Carbon) research project yields a material that is in high demand: pure carbon. “It’s needed to produce batteries and building materials and in the paint industry and agriculture,” says project coordinator Benjamin Dietrich. “So far, most carbon has come from fossil sources.” The approach taken by the Karlsruhe researchers kills two birds with one stone by removing CO2 and simultaneously producing a sought-after raw material. The process, which made headlines all over Germany, has demonstrated its worth on a small scale. With their test system, the researchers can produce half a kilogram of carbon per day. They plan to gradually scale up their operation. Processes like this are designated CCU – carbon capture and utilization; the carbon dioxide is put to use as part of a new product. There is no shortage of ideas for such products. NECOC is seen as having a bright future in this relatively young field.

The history of CO2 storage goes back much further, nearly three decades. It began in Norway, where the government introduced a CO2 tax. A company that produced natural gas decided to bury the carbon dioxide underground. “A lot of CO2 finds its way to the surface when natural gas is extracted. It’s usually separated from the natural gas and then escapes into the atmosphere,” says Schilling, the expert from KIT. “But in this case, they drilled a second hole and sent it back underground – into a different layer than the one the gas comes from.” Thick and impermeable rock layers made sure the CO2 stayed underground – the cheese bell effect.

Schilling played a leading role in a large-scale research project that started afterward in Germany. A pilot CO2 storage plant with several 800-meter-deep holes was built in Ketzin, about 40 kilometers from Berlin. The Helmholtz Centre Potsdam, German Research Centre for Geosciences (GFZ) backed the project, in which engineers and scientists from the fields of geology, geophysics, geochemistry and simulation took part. When it ended in 2017, the project was a complete success. The researchers gained an ever better understanding of the processes going on underground as they investigated how some of the CO2 was incorporated into pores in the rock, how some was dissolved in water, and how the CO2 was ultimately mineralized into limestone.

CCS technology has not been put to use in Germany due to political resistance, even though there are many places where it could be effective. Cement factories, power plants that burn fossil fuels, and other factories that emit a lot of carbon dioxide could capture the emitted gas on the spot and store it underground. Experts estimate that 6 to 12 billion tons of carbon dioxide could be safely stored underground in Germany.

In any case, according to Schilling, the technology is ready for use in demonstration projects. To apply it at larger scales, further development is still needed.