A cycle for plastics

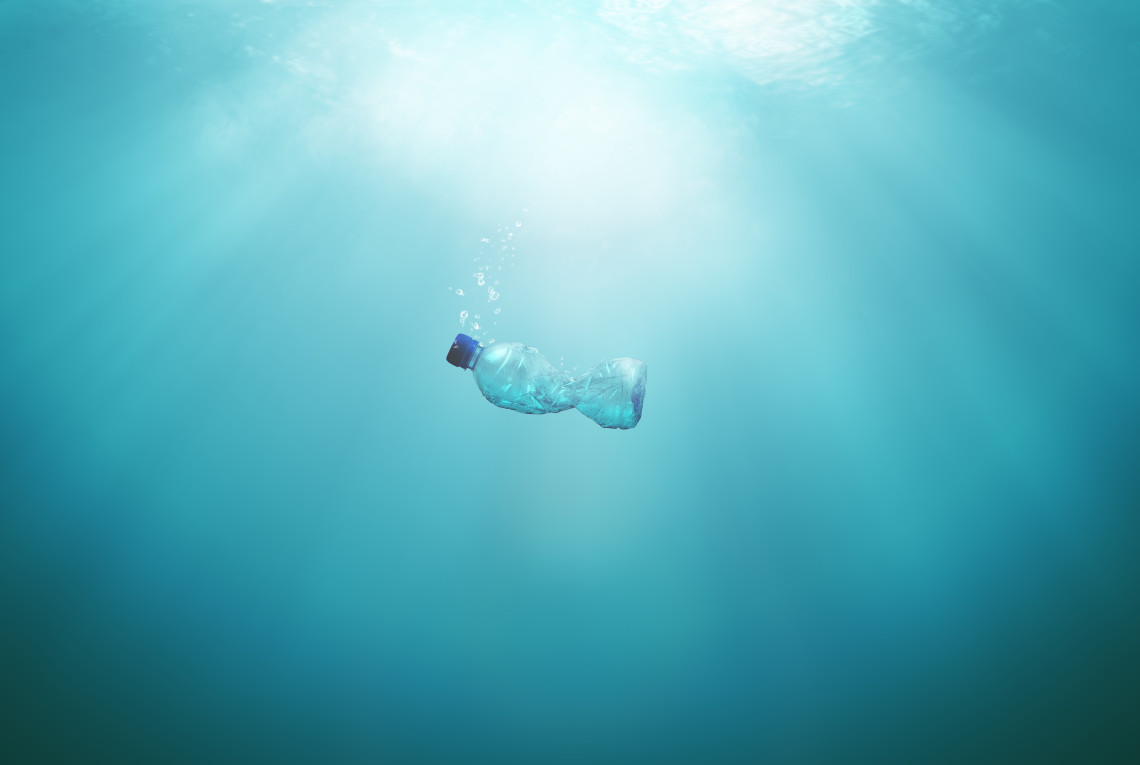

Pollution and mountains of garbage: Plastic trash is a severe problem. But since it is hard to imagine life without plastics, researchers are looking for ways to deal with them more sustainably.

Our use of plastics is symptomatic of our careless use of resources worldwide. Though they are produced with great effort from valuable resources, plastic products end up in the trash after being used only once, at least in the case of the packaging in which most plastics are used. According to a report by the Organisation for Economic Co-operation and Development (OECD), only nine percent of plastic trash worldwide is recycled into new materials. The rest is burned, deposited in landfills, or ends up in the environment. That has an impact on people and animals.

“Plastics as such aren’t bad; as raw materials they have enormous potential,” says Hartmut Pflaum, a scientist at the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT and Head of Office at the Fraunhofer Cluster of Excellence Circular Plastics Economy. Plastics are cheap, versatile and light, which in many cases reduces the costs and energy consumption involved in transporting them. But the problem is that they are made from oil and end up in the environment, where they remain for decades or even centuries. And the incineration of non-recyclable plastics releases carbon dioxide, a hazard for the climate. “When plastics were developed in the 50s and 60s, nobody thought about how long they would last. Now that’s our problem,” says Nick Wierckx, a biotechnology expert at Forschungszentrum Jülich. The recyclability of plastics is a priority for him because it means “we keep it in circulation.”

Changing from the linear plastic economy – production, use, disposal – to a circular economy in which materials are reused for a long time is also a goal of the European Union’s (EU) plastics strategy, which calls for all plastic packaging on the market in the EU to be recyclable by 2030. That is not the case so far. Plastics are not all alike. For example, PET (polyethylene terephthalate) used in bottles and collected separately can be easily shredded, melted and formed into new products. This is more difficult with other plastics such as PVC (polyvinyl chloride). Packaging made of combinations of plastics is especially poorly recyclable. “Sometimes you don’t notice that a packaging film can consist of 11 layers,” says UMSICHT researcher Pflaum. “These multilayer plastics are extremely hard or impossible to recycle.”

Bioplastics

The term “bioplastics” is used in many ways and sometimes causes confusion. For one thing, it can designate bio-based materials without any indication of their recyclability. For another, it often refers to biodegradable plastics, i.e., plastics that can be broken down in nature by microorganisms. Whether they are produced from oil or biomass is irrelevant.

Pflaum sees two approaches to solving this problem. One involves the products, where “fewer kinds of plastics, less composite packaging, and fewer but more compatible chemical additives” should be used. The other involves improving the recycling process, something researchers are working on. For example, they are investigating how plastics that are resistant to classical reprocessing methods can be broken down after all.

Chemical processes are a possible way to break this mixed fraction down into its constituents. “What I get in the end isn’t a solid plastic, it’s molecules that I can use to synthesize new plastics,” says Pflaum. Wierckx’s working group at Forschungszentrum Jülich researches biotechnology methods, setting bacteria on composite plastics. “That’s the real power of biology, that we can work with such a mixed stream of materials,” says Wierckx.

However, neither the energy-intensive chemical processes nor the biotechnology processes have been in large-scale commercial use thus far. Wierckx warns that the current cost-benefit calculation is not quite right, saying: “Petroleum-based plastics are too cheap. Their impact on the climate and the pollution they cause aren’t included in their price.” In his opinion, a circular economy for plastics also means developing new materials made from biological components, “and doing it so they’re recyclable from the beginning.” In cases where plastics do end up in the environment, biodegradability is also an advantage; then the material can rot naturally.

The speed with which a smoothly operating circular economy for plastics can be implemented depends not only on technical solutions but also on political ones. “Regulations don’t affect product design so much,” Pflaum says. The path to take here is quotas on the use of recycled materials, i.e., regulations on how much recycled material has to be used in a product. “So you don’t say a certain amount of waste has to go into recycling. Instead, you say a certain amount of recycled material has to be included in a new product.” But that would mean closer cooperation between the recycling industry and product designers. How that is to succeed is also a subject of ongoing research.